Showing 1–12 of 17 resultsSorted by latest

Sling rope round circular hoop with inspection window in the black cover. ( 2 Tons )

Sling rope round circular hoop with inspection window in the black cover. ( 1 Ton )

Steel sling ( 16 tons) (Contact for Price and availability)

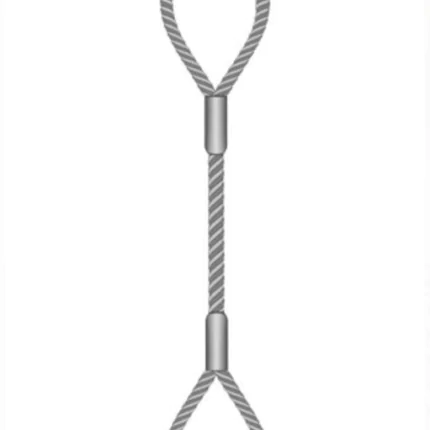

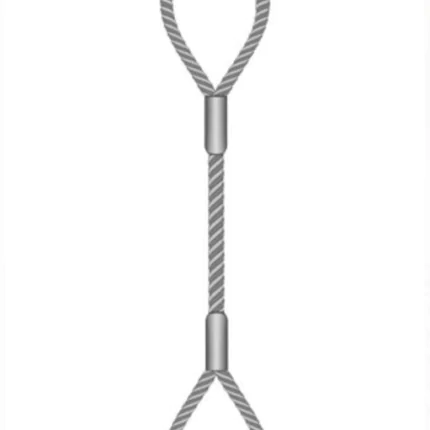

Eye to Eye steel slings are most commonly used as safeties when hanging truss with spansets or for direct suspension of audio and lighting equipment. You can use it singularly or in a pair, Prices is per one cable, please choose characteristics and WLL below.

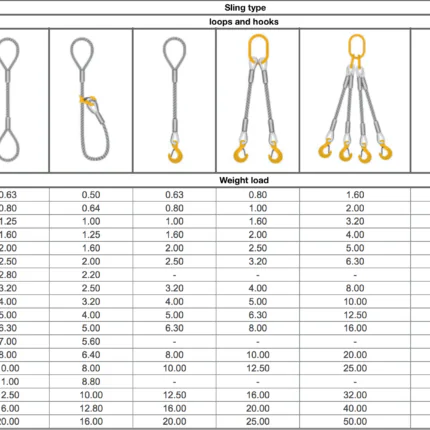

100mm = 3.9 inches

Rope slings are the most common type of load-handling devices. In many countries, most of the lifting operations are traditionally carried out using steel rope slings. The reason for such popularity is the accumulated rich experience of their use, the possibility of using various types of slinging, the prevalence and cheapness of the products themselves, as well as the absence until recently of alternative types of lifting lines from more modern materials. Cable rope slings have a number of advantages, among them: - high load-carrying capacity and flexibility; - less labor-intensive in manufacturing than other types of slings; - have sufficient reliability and stability to sharp dynamic loads, as the rope smoothes them; - the destruction of the rope during the operation is not sudden but gradual, which allows you to monitor the condition of the line and remove them from time to time. Traditionally, there are two types of loops: 1. Hand braid (interlacing strands of the free end of the rope in the body of the sling). 2. Crimping in the press with an aluminum or steel sleeve. The company sell lifting slings of any types, designs, lengths, carrying capacities, on its own production site. The production facilities are equipped with modern press equipment, hand-braided machines, and a test stand. We work with light and galvanized ropes with diameters of 4,0 - 65,0 mm, which makes it possible to manufacture slings with a lifting capacity of 0.25 - 60.0 tons. Quantity for delivery - from 1 unit. The most common designs of slings are given in the table.Steel sling ( 12.5 tons) (Contact for Price and availability)

Eye to Eye steel slings are most commonly used as safeties when hanging truss with spansets or for direct suspension of audio and lighting equipment. You can use it singularly or in a pair, Prices is per one cable, please choose characteristics and WLL below.

100mm = 3.9 inches

Rope slings are the most common type of load-handling devices. In many countries, most of the lifting operations are traditionally carried out using steel rope slings. The reason for such popularity is the accumulated rich experience of their use, the possibility of using various types of slinging, the prevalence and cheapness of the products themselves, as well as the absence until recently of alternative types of lifting lines from more modern materials. Cable rope slings have a number of advantages, among them: - high load-carrying capacity and flexibility; - less labor-intensive in manufacturing than other types of slings; - have sufficient reliability and stability to sharp dynamic loads, as the rope smoothes them; - the destruction of the rope during the operation is not sudden but gradual, which allows you to monitor the condition of the line and remove them from time to time. Traditionally, there are two types of loops: 1. Hand braid (interlacing strands of the free end of the rope in the body of the sling). 2. Crimping in the press with an aluminum or steel sleeve. The company sell lifting slings of any types, designs, lengths, carrying capacities, on its own production site. The production facilities are equipped with modern press equipment, hand-braided machines, and a test stand. We work with light and galvanized ropes with diameters of 4,0 - 65,0 mm, which makes it possible to manufacture slings with a lifting capacity of 0.25 - 60.0 tons. Quantity for delivery - from 1 unit. The most common designs of slings are given in the table.Steel sling ( 10 tons) (Contact for Price and availability)

Eye to Eye steel slings are most commonly used as safeties when hanging truss with spansets or for direct suspension of audio and lighting equipment. You can use it singularly or in a pair, Prices is per one cable, please choose characteristics and WLL below.

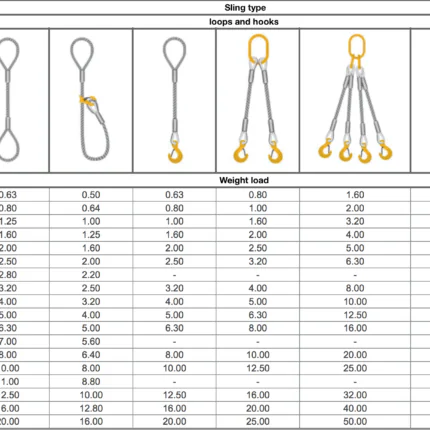

100mm = 3.9 inches

Rope slings are the most common type of load-handling devices. In many countries, most of the lifting operations are traditionally carried out using steel rope slings. The reason for such popularity is the accumulated rich experience of their use, the possibility of using various types of slinging, the prevalence and cheapness of the products themselves, as well as the absence until recently of alternative types of lifting lines from more modern materials. Cable rope slings have a number of advantages, among them: - high load-carrying capacity and flexibility; - less labor-intensive in manufacturing than other types of slings; - have sufficient reliability and stability to sharp dynamic loads, as the rope smoothes them; - the destruction of the rope during the operation is not sudden but gradual, which allows you to monitor the condition of the line and remove them from time to time. Traditionally, there are two types of loops: 1. Hand braid (interlacing strands of the free end of the rope in the body of the sling). 2. Crimping in the press with an aluminum or steel sleeve. The company sell lifting slings of any types, designs, lengths, carrying capacities, on its own production site. The production facilities are equipped with modern press equipment, hand-braided machines, and a test stand. We work with light and galvanized ropes with diameters of 4,0 - 65,0 mm, which makes it possible to manufacture slings with a lifting capacity of 0.25 - 60.0 tons. Quantity for delivery - from 1 unit. The most common designs of slings are given in the table.Steel sling ( 20 tons) (Contact for Price and availability)

Eye to Eye steel slings are most commonly used as safeties when hanging truss with spansets or for direct suspension of audio and lighting equipment. You can use it singularly or in a pair, Prices is per one cable, please choose characteristics and WLL below.

100mm = 3.9 inches

Rope slings are the most common type of load-handling devices. In many countries, most of the lifting operations are traditionally carried out using steel rope slings. The reason for such popularity is the accumulated rich experience of their use, the possibility of using various types of slinging, the prevalence and cheapness of the products themselves, as well as the absence until recently of alternative types of lifting lines from more modern materials. Cable rope slings have a number of advantages, among them: - high load-carrying capacity and flexibility; - less labor-intensive in manufacturing than other types of slings; - have sufficient reliability and stability to sharp dynamic loads, as the rope smoothes them; - the destruction of the rope during the operation is not sudden but gradual, which allows you to monitor the condition of the line and remove them from time to time. Traditionally, there are two types of loops: 1. Hand braid (interlacing strands of the free end of the rope in the body of the sling). 2. Crimping in the press with an aluminum or steel sleeve. The company sell lifting slings of any types, designs, lengths, carrying capacities, on its own production site. The production facilities are equipped with modern press equipment, hand-braided machines, and a test stand. We work with light and galvanized ropes with diameters of 4,0 - 65,0 mm, which makes it possible to manufacture slings with a lifting capacity of 0.25 - 60.0 tons. Quantity for delivery - from 1 unit. The most common designs of slings are given in the table.Steel sling ( 6.3 tons) (Contact for Price and availability)

Eye to Eye steel slings are most commonly used as safeties when hanging truss with spansets or for direct suspension of audio and lighting equipment. You can use it singularly or in a pair, Prices is per one cable, please choose characteristics and WLL below.

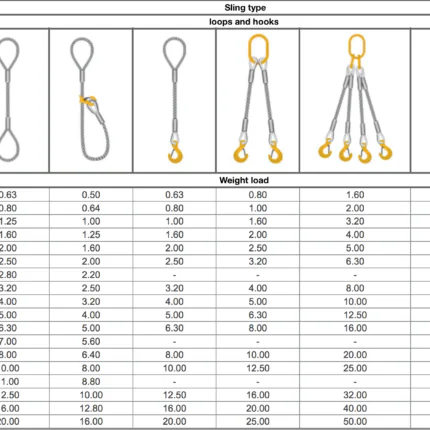

100mm = 3.9 inches

Rope slings are the most common type of load-handling devices. In many countries, most of the lifting operations are traditionally carried out using steel rope slings. The reason for such popularity is the accumulated rich experience of their use, the possibility of using various types of slinging, the prevalence and cheapness of the products themselves, as well as the absence until recently of alternative types of lifting lines from more modern materials. Cable rope slings have a number of advantages, among them: - high load-carrying capacity and flexibility; - less labor-intensive in manufacturing than other types of slings; - have sufficient reliability and stability to sharp dynamic loads, as the rope smoothes them; - the destruction of the rope during the operation is not sudden but gradual, which allows you to monitor the condition of the line and remove them from time to time. Traditionally, there are two types of loops: 1. Hand braid (interlacing strands of the free end of the rope in the body of the sling). 2. Crimping in the press with an aluminum or steel sleeve. The company sell lifting slings of any types, designs, lengths, carrying capacities, on its own production site. The production facilities are equipped with modern press equipment, hand-braided machines, and a test stand. We work with light and galvanized ropes with diameters of 4,0 - 65,0 mm, which makes it possible to manufacture slings with a lifting capacity of 0.25 - 60.0 tons. Quantity for delivery - from 1 unit. The most common designs of slings are given in the table.Steel sling ( 4 tons) (Contact for Price and availability)

Eye to Eye steel slings are most commonly used as safeties when hanging truss with spansets or for direct suspension of audio and lighting equipment. You can use it singularly or in a pair, Prices is per one cable, please choose characteristics and WLL below.

100mm = 3.9 inches

Rope slings are the most common type of load-handling devices. In many countries, most of the lifting operations are traditionally carried out using steel rope slings. The reason for such popularity is the accumulated rich experience of their use, the possibility of using various types of slinging, the prevalence and cheapness of the products themselves, as well as the absence until recently of alternative types of lifting lines from more modern materials. Cable rope slings have a number of advantages, among them: - high load-carrying capacity and flexibility; - less labor-intensive in manufacturing than other types of slings; - have sufficient reliability and stability to sharp dynamic loads, as the rope smoothes them; - the destruction of the rope during the operation is not sudden but gradual, which allows you to monitor the condition of the line and remove them from time to time. Traditionally, there are two types of loops: 1. Hand braid (interlacing strands of the free end of the rope in the body of the sling). 2. Crimping in the press with an aluminum or steel sleeve. The company sell lifting slings of any types, designs, lengths, carrying capacities, on its own production site. The production facilities are equipped with modern press equipment, hand-braided machines, and a test stand. We work with light and galvanized ropes with diameters of 4,0 - 65,0 mm, which makes it possible to manufacture slings with a lifting capacity of 0.25 - 60.0 tons. Quantity for delivery - from 1 unit. The most common designs of slings are given in the table.Steel sling ( 3.2 tons) (Contact for Price and availability)

Eye to Eye steel slings are most commonly used as safeties when hanging truss with spansets or for direct suspension of audio and lighting equipment. You can use it singularly or in a pair, Prices is per one cable, please choose characteristics and WLL below.

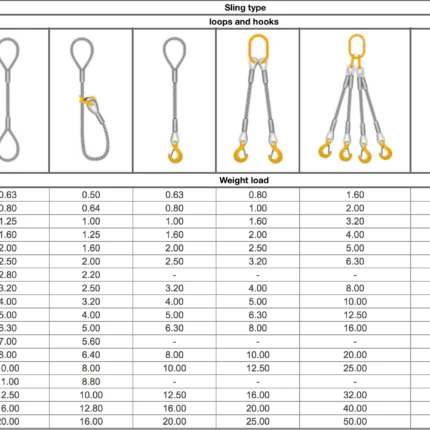

100mm = 3.9 inches

Rope slings are the most common type of load-handling devices. In many countries, most of the lifting operations are traditionally carried out using steel rope slings. The reason for such popularity is the accumulated rich experience of their use, the possibility of using various types of slinging, the prevalence and cheapness of the products themselves, as well as the absence until recently of alternative types of lifting lines from more modern materials. Cable rope slings have a number of advantages, among them: - high load-carrying capacity and flexibility; - less labor-intensive in manufacturing than other types of slings; - have sufficient reliability and stability to sharp dynamic loads, as the rope smoothes them; - the destruction of the rope during the operation is not sudden but gradual, which allows you to monitor the condition of the line and remove them from time to time. Traditionally, there are two types of loops: 1. Hand braid (interlacing strands of the free end of the rope in the body of the sling). 2. Crimping in the press with an aluminum or steel sleeve. The company sell lifting slings of any types, designs, lengths, carrying capacities, on its own production site. The production facilities are equipped with modern press equipment, hand-braided machines, and a test stand. We work with light and galvanized ropes with diameters of 4,0 - 65,0 mm, which makes it possible to manufacture slings with a lifting capacity of 0.25 - 60.0 tons. Quantity for delivery - from 1 unit. The most common designs of slings are given in the table.Steel sling ( 2.8 tons) (Contact for Price and availability)

Eye to Eye steel slings are most commonly used as safeties when hanging truss with spansets or for direct suspension of audio and lighting equipment. You can use it singularly or in a pair, Prices is per one cable, please choose characteristics and WLL below.

100mm = 3.9 inches

Rope slings are the most common type of load-handling devices. In many countries, most of the lifting operations are traditionally carried out using steel rope slings. The reason for such popularity is the accumulated rich experience of their use, the possibility of using various types of slinging, the prevalence and cheapness of the products themselves, as well as the absence until recently of alternative types of lifting lines from more modern materials. Cable rope slings have a number of advantages, among them: - high load-carrying capacity and flexibility; - less labor-intensive in manufacturing than other types of slings; - have sufficient reliability and stability to sharp dynamic loads, as the rope smoothes them; - the destruction of the rope during the operation is not sudden but gradual, which allows you to monitor the condition of the line and remove them from time to time. Traditionally, there are two types of loops: 1. Hand braid (interlacing strands of the free end of the rope in the body of the sling). 2. Crimping in the press with an aluminum or steel sleeve. The company sell lifting slings of any types, designs, lengths, carrying capacities, on its own production site. The production facilities are equipped with modern press equipment, hand-braided machines, and a test stand. We work with light and galvanized ropes with diameters of 4,0 - 65,0 mm, which makes it possible to manufacture slings with a lifting capacity of 0.25 - 60.0 tons. Quantity for delivery - from 1 unit. The most common designs of slings are given in the table.Steel sling ( 2.5 tons) (Contact for Price and availability)

Eye to Eye steel slings are most commonly used as safeties when hanging truss with spansets or for direct suspension of audio and lighting equipment. You can use it singularly or in a pair, Prices is per one cable, please choose characteristics and WLL below.

100mm = 3.9 inches

Rope slings are the most common type of load-handling devices. In many countries, most of the lifting operations are traditionally carried out using steel rope slings. The reason for such popularity is the accumulated rich experience of their use, the possibility of using various types of slinging, the prevalence and cheapness of the products themselves, as well as the absence until recently of alternative types of lifting lines from more modern materials. Cable rope slings have a number of advantages, among them: - high load-carrying capacity and flexibility; - less labor-intensive in manufacturing than other types of slings; - have sufficient reliability and stability to sharp dynamic loads, as the rope smoothes them; - the destruction of the rope during the operation is not sudden but gradual, which allows you to monitor the condition of the line and remove them from time to time. Traditionally, there are two types of loops: 1. Hand braid (interlacing strands of the free end of the rope in the body of the sling). 2. Crimping in the press with an aluminum or steel sleeve. The company sell lifting slings of any types, designs, lengths, carrying capacities, on its own production site. The production facilities are equipped with modern press equipment, hand-braided machines, and a test stand. We work with light and galvanized ropes with diameters of 4,0 - 65,0 mm, which makes it possible to manufacture slings with a lifting capacity of 0.25 - 60.0 tons. Quantity for delivery - from 1 unit. The most common designs of slings are given in the table.Steel sling ( 2 tons) (Contact for Price and availability)

Eye to Eye steel slings are most commonly used as safeties when hanging truss with spansets or for direct suspension of audio and lighting equipment. You can use it singularly or in a pair, Prices is per one cable, please choose characteristics and WLL below.

100mm = 3.9 inches

Rope slings are the most common type of load-handling devices. In many countries, most of the lifting operations are traditionally carried out using steel rope slings. The reason for such popularity is the accumulated rich experience of their use, the possibility of using various types of slinging, the prevalence and cheapness of the products themselves, as well as the absence until recently of alternative types of lifting lines from more modern materials. Cable rope slings have a number of advantages, among them: - high load-carrying capacity and flexibility; - less labor-intensive in manufacturing than other types of slings; - have sufficient reliability and stability to sharp dynamic loads, as the rope smoothes them; - the destruction of the rope during the operation is not sudden but gradual, which allows you to monitor the condition of the line and remove them from time to time. Traditionally, there are two types of loops: 1. Hand braid (interlacing strands of the free end of the rope in the body of the sling). 2. Crimping in the press with an aluminum or steel sleeve. The company sell lifting slings of any types, designs, lengths, carrying capacities, on its own production site. The production facilities are equipped with modern press equipment, hand-braided machines, and a test stand. We work with light and galvanized ropes with diameters of 4,0 - 65,0 mm, which makes it possible to manufacture slings with a lifting capacity of 0.25 - 60.0 tons. Quantity for delivery - from 1 unit. The most common designs of slings are given in the table.For technical maintenance of events and stage you will find a huge amount of related equipment and accessories.

Please feel free to contact us with specific request, we can also add your logo into our products without additional fees.

For orders over 2000 USD we will provide you with 7% discount, for orders over 10000 USD you will receive 15% discount and over 15000 – 20%.

Please note that delivery fees will be calulated separately, depending on quantity of your order. For each line of products after your order is placed, we will notify you with the weight of purchased item and related delivery costs.

Aerial rigging cables in circus and other entertainment are one of the most important subjects. Rigging in show business, in circus, theatre and other various events and performances can be decided into two main categories – arena style and theatre rigging, but with two categories, still the same skills and knowledge base apply.

Rigging for theatre or another permanently build structure usually involves permanent fly aerial system, another category is arena, circus or another venues and entertainment that take place in temporary structures, it could be convention centre, circus tent, warehouse or even outside.

At the same time, particularly Circus rigging especially for aerial acrobatic equipment to support performers during their acts with dynamic loads, stabilizing rigging for large size tension systems such for example big top for Cirque du Soleil, can be considered separate field in rigging.

In any case, all physical properties and principles as well as engineering standards and codes, professional skills apply in theatre or arena rigging, also basically the same techniques devices and props are used.

Trusses, talrep systems, chain motors more often used in theatre rigging comparing to circus, event rigging, travelling arena circus groups such as regular Cirque du Soleil shows in arena’s commonly use theatrical type of rigging. In arena or circus tents circus shows, frames, crane bars, tackle systems are commonly and widely used supporting and tensioning nets used in aerial acts for safety reasons.

For example for tight wires, either high or low it requires substantial capacity for load because tight wire performers use high tensed wires in their acts. At red circle shop customers can order aerial rigging cables for sale as well as other accessories and also high tensed tight wire systems with adjustable heights.

Another type is an automated rigging, wide used in various traditional, contemporary circuses, sometime even in juggling performances all around the world, for example at cirque du soleil automated aerial rigging equipment is quite common practise for aerial acts with performers also for scenic equipment.

In theatrical rigging it could any type of rigging system from flying systems and dead pull scenery to counterweight rigging system, various winches, hoist and also automated systems for rigging also used to fly artists or different equipment for performance.

At Red Circle Shop you can order various types of ropes, cables, chains with any type of load capacity.

Online store Red Circle Shop offer discounts to qualifying non for profit circus organizations, artists in need. Customers can order various types of rigging equipment at Red Circle Shop.

There is different professions related with rigging,

Aerial / Acrobatics

Aerial / Acrobatics Aerial acrobatics

Aerial acrobatics Aerial Cube / LED Cube

Aerial Cube / LED Cube Aerial Hoop, Lyra, Sphere, Spiral, Heart, Chandelier, Aerial lollipop

Aerial Hoop, Lyra, Sphere, Spiral, Heart, Chandelier, Aerial lollipop Aerial straps

Aerial straps Aerial Trapeze

Aerial Trapeze Cyr Wheel / German Wheel / Crossed wheel

Cyr Wheel / German Wheel / Crossed wheel Crossed Wheel

Crossed Wheel Cyr Wheel

Cyr Wheel German Wheel / Rhönrad

German Wheel / Rhönrad Cyr Wheel / German Wheel by Zimmermann

Cyr Wheel / German Wheel by Zimmermann Slinky Costumes

Slinky Costumes Juggling Equipment

Juggling Equipment Tight-wire self standing

Tight-wire self standing Pole

Pole Pole dance

Pole dance American Wheel of death

American Wheel of death Theatrical Mechanics – Stage Equipment & Rigging Systems

Theatrical Mechanics – Stage Equipment & Rigging Systems Mobile constructions

Mobile constructions